15Years! Seamark ZHUOMAO SMT/repair shop ZM R7220A with CCD camera Motherboard Repair BGA Rework System

Company Information:

Name: |

15Years! Seamark ZHUOMAO SMT/repair shop ZM R7220A with CCD camera Motherboard Repair BGA Rework System |

Category: |

|

Offered by: |

|

15Years! Seamark ZHUOMAO SMT/repair shop ZM R7220A with CCD camera Motherboard Repair BGA Rework System Description:

Product Description

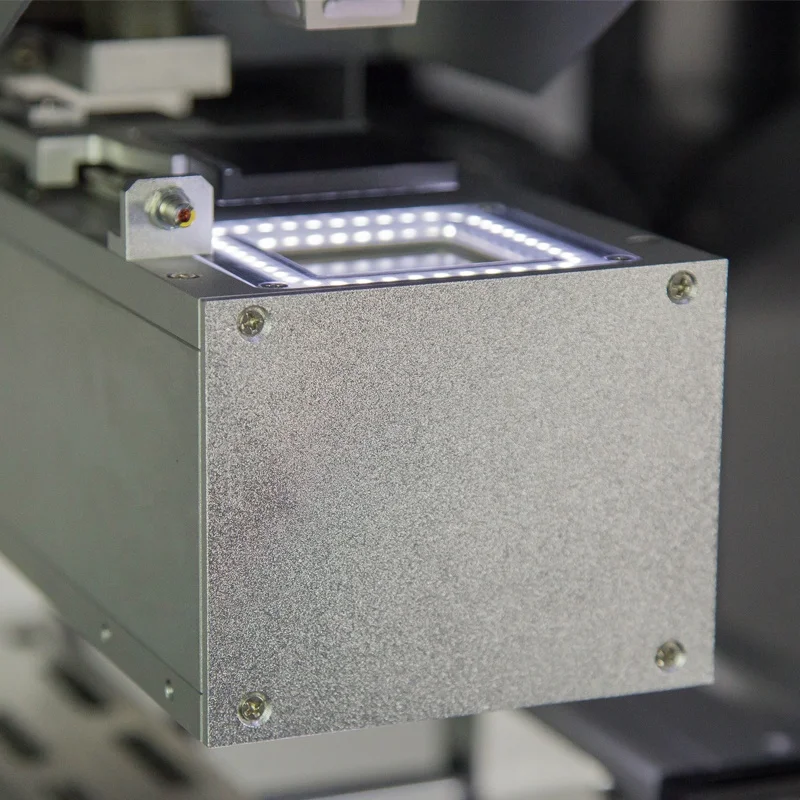

High Perfomance bga rework station heater ZM R7220A with CCD camera

Product Application

ZM-R7220A BGA rework station is the hot selling bga rework station during 2016, it has obtained great popular from global user.

It can desolder and solder all the BGA Chip (temperature accuracy within ±1℃), remove and repair different motherboard BGA IC chip and other components (mounting accuracy within ±0.02mm, Lead free & lead available). It can cut down the production cost from reworking the bad soldering IC Chip during the PCB assembly procedure. With Optical alignment system, you can rework the BGA well easily.

|

SPECIFICATIONS FOR ZM-R7220A BGA REWORK STATION |

|||

|

Power |

AC 220V±10% 50/60 Hz |

Positioning |

V-groove, PCB support |

|

Total Power |

Max 5300W |

Sensors |

1 pc |

|

Heater power |

Top heater 1200W Bottom heater 1200W IR heater 2700W |

||

|

Electrical materials |

Intelligence Programmable controller, support connect computer |

||

|

Temperature control |

K-type thermocouple (Closed Loop), independence temperature control, accuracy within±1℃ |

||

|

PCB size |

Max 415×370 mm Min 6×6 mm |

Dimensions |

L650×W640×H960 mm |

|

BGA chip |

Max 60×60mm Min 2×2 mm |

Weight |

79kg |

Video Link:

www.seamarkxray.com

Main Features

●3 independent control heaters

① Top and bottom heaters are hot-air heating, the third IR heater is infrared heating, the top and bottom heaters can heat PCB from upper and bottom at the same time. temperature accuracy within ±1℃,there are multi segments can be set at the same time; IR preheating area is adjustable according to desire requests, to make PCB heating evenly.

② It can heat PCB board and bga chips at the same time. And the third IR heater can preheat the PCB board from bottom, to avoid PCB from deformation during repair process. The top and bottom heaters heat independently;

③ Choose high accurate K type close-loop thermocouple, and PID parameters automatic adjustment system;it can show seven temperature curves and the millions of groups data can be saved through U storage device,with instant curves analysis function and analyzing BGA temperature at any time; the sensor is for precise temperature testing.

●Precise optical alignment system

Adopt adjustable CCD color optical system, with a beam split, zoom in, zoom out and micro-adjust functions, has automatic chromatism resolution and brightness adjustment system, amplify to 230 X, mounting accuracy within ±0.01mm.

●Multi-function operation system

① Adopt high definition human-machine interface, available for setting "set up" and "operate" to avoid error settings, The top heater device and mounting head 2 in 1 design, with automatic identify BGA chips and mounting height, it is of automatic soldering and desoldering function.it can set 6 segments rising temperature and 6 segments activity temperature, and can save N groups temperature profiles. Adopted all kinds of BGA nozzles, with 360° rotation, easy for installation and replacement, customized is available;

②V-groove PCB support, with rapid, convenient and accurate positioning, can fit for all kinds of PCB board; Flexible and removable universal fixture has protective effects and no damage to the PCB board, suitable for all kinds of sizes of BGA repair.

●Superior safety functions

With CE certification; after desoldering and soldering, there is alarming. when temperature goes out of control;the circuit will automatically power off, it is of double over-temperature protection function. Temperature parameter has a passwordto avoid from arbitrary changes, with superior safety protection functions, can protect PCB board components and the machine from damage at any abnormal situation.

Certifications

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Free professional training.

* Warranty: One year. Lifelong Technical Support.

* Engineers available to service machinery overseas.

Packing & Delivery

Our Company

Seamark ZM Technology Group (H.K.) CO., LTD

Seamark ZM Technology Group (Zhuomao Technology) was established in 2004 with over 200 employees and 5000 square meter. Zhuomao has been specializing in SMT Equipments for electronic products and LED SMT production line, such as Solder Paste Stencil Printer, Auto Pick up and Place Machine, Reflow Oven, X-Ray inspection System, and BGA Rework Station, ect. We gained more than 40 patents, and all machines passed the international CE Certification, ISO9001Quality System Inspection Certification and so on. Zhuomao SMT Equipments not only meets the demand of domestic market, but has also been sold around the world. We have around 100 agents and cooperator in Europe, Asia, Australia and Africa, the Middle East and other countries.

In order to meet the international market demand and customer customization requirement, we keep developing and researching different level of machines for different customer choice.

Seamark ZM cooperative partner

FAQ

1. How about the package? Is it safe during the delivery?

All PCB X-ray machine is packed by standard strong wooden carton.It is safe when shipping.

2. What is the delivery way? How many days will the machine arrrive us?

We will ship the machine by DHL,Fedex, UPS,etc (Door to Door Service), around 5 days to arrive.

Or by Air to your airport (Door to Airport Service ), around 3 days to arrive.

Or by Sea to the seaport, Minium CBM requirement : 1 CBM, around 30days to arrive.

3. Do you provide the Warranty? How about the after sales service?

1 year warranty free for spare parts, Whole life technicial support.

We have professional after sales team, if any question, assistant videos are also provided in after-sale service.

4. If we come to your factory, will you provide the free training?

Yes, warmly welcome you to visit our factory, we will arrange the free training for you.

5. What's the payment terms?

We accept the payment terms: Bank transfer, WesterUnion, Moneygram, etc.

Related Products

For more details of High Recommend BGA Repair Machine Motherboard IC Removing Machine, please contact us. Looking forward to your inquiry.

Contact information:

☺Ms. Joy Rong

☞Mobile/ WhatsApp/ Wechat: +86 18779975930

15Years! Seamark ZHUOMAO SMT/repair shop ZM R7220A with CCD camera Motherboard Repair BGA Rework System was added in Mar 2019

15Years! Seamark ZHUOMAO SMT/repair shop ZM R7220A with CCD camera Motherboard Repair BGA Rework System has been viewed 417 times

6 More Products from Seamark zm Tech Group :

.png)

1.jpg)

.jpg)