Microfocus X-Ray inspect equipment X-6600 for PCBA solder inspection

Company Information:

Name: |

Microfocus X-Ray inspect equipment X-6600 for PCBA solder inspection |

Category: |

|

Offered by: |

|

Microfocus X-Ray inspect equipment X-6600 for PCBA solder inspection Description:

Microfocus X-Ray inspect equipment X-6600 for PCBA solder inspection

Product Application:

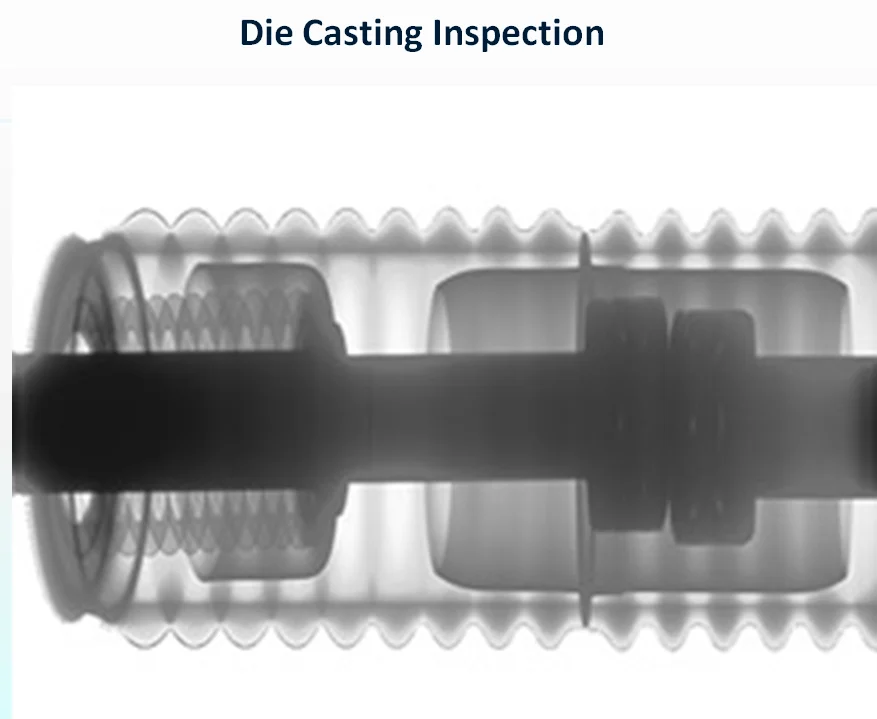

X-Ray inspection is a method of non-destructive testing where many types of manufactured components can be examined to verify the internal structure via the penetration power from X-Ray.

Seamark Zhuomao X-6600 X-ray inspection machine has been widely applied to

PCBA, LED, SMT, semiconductor, battery, casting, plastic,connectors,cable etc

Specific application:

1) Defect inspection in IC encapsulation, e.g.: layer separation, cracking, void, and line integrity.

2) Measuring chip size, measuring line curvature, measuring the proportion of solder area of components.

3) Possible defects in PCB manufacturing processes, e.g.: misalignment, solder bridge and open.

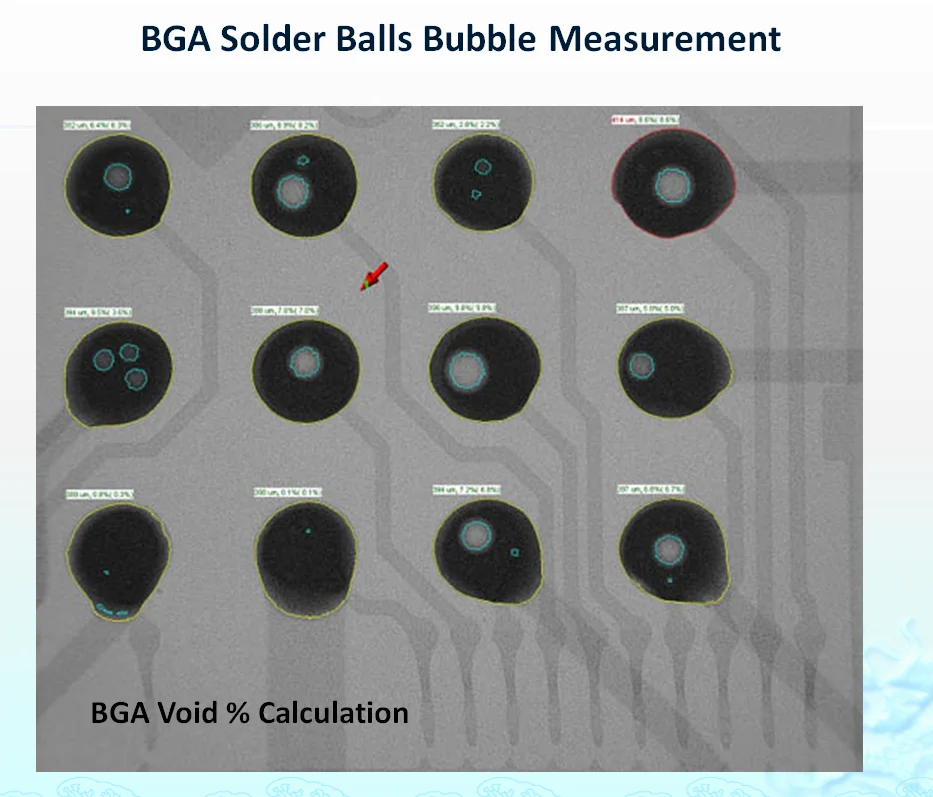

4) SMT solder short, cold solder, component shifted, solder insufficient, solder void inspection and measurement.

5) Defect inspection of open, short or abnormal connections that may occur in automotive wiring harnesses and connectors.

6) Inner rupture or hollow inspection in plastic or metal.

7) Battery stacking uniformity, electrode welding inspection.

Contact Rita Li(whatsapp/wechat/viber:0086-134 3448 1030) for customised machine and function for your products and requirements!

|

Main Function and advantage |

|

|

Function |

Advantages |

|

X-ray tube and detector can move along Z direction |

Fault less than 2.5μm can be detected. |

|

Voltage and current set by software |

Easy to maintain, long service life. |

|

Speed of table moving along X-Y direction can be adjusted |

Easy operation, training time for operator is short. |

|

Powerful CNC Measuring Function, can test automatically, testing program can be edited. |

Suitable for mass detection |

|

High-definition digital flat panel detector. |

semi-automatic identification for OK/NG products. |

|

Large navigation view, table will move to where you click the mouse. |

Highly reliable and high-precision test |

|

Latest image processing technology, can numerically calculate the size of the defect and area size. |

Suitable to different samples with large sizes. |

|

Accurately detect insufficient solder/cold solder and blob ratio of PCB board, can also calculate the size, import the result into the sheet and display on the screen |

samples can be observed with a unique perspective |

Main Features

Stage Control Parts

1.By the space bar to adjust stage speed: Slow, Constant and Fast

2.Keyboard control X, Y, Z axis motion and the inclined angle

3.User can detect the samples automatically by programmed

4.Large navigation window, the image is very clear, mouse clicks will move the stage to a position that you need.

CNC programming

1. A simple mouse clicks will create a Testing procedures

2. The stage can be X, Y axis positioning; X-ray tube and the detector will be positioning in Z axis

3. Software setting voltage and current

4. Image setting: Brightness, contrast, automatic gain and exposure

5. User can set the program switch pause time

6. The anti-collision system can meet the maximum tilt and observe objects

7. Automatic analysis BGA diameter, Void ratio, size and roundness

Full Automatic Testing Procedures

Click programming without the need for operator intervention on the component can detect automatically.

Technical Parameters

|

Specification for X-6600 |

||

|

X Ray tube |

Tube Type |

Sealed |

|

Max Tube voltage |

90kV(130kV optional) |

|

|

Maximum tube current |

0.12mA |

|

|

Focal spot size |

5μm |

|

|

Magnification |

Geometric magnification:150X |

|

|

Flat Panel Detector |

Image speed |

30 fps |

|

Resolution |

1176*1104 |

|

|

Inclined Angle |

60° |

|

|

Specification |

Table size |

540mm*450mm (Could customize) |

|

Dimension |

L1650mm*W1537mm*H1700mm |

|

|

Net weight |

1300kg |

|

|

Input voltage |

AC 110-220V (+10%) |

|

|

X ray Leakage |

≤1 u Sv/h |

|

|

Operation system |

Windows 7 Seamark3.0 |

|

|

Total power |

1.5 KW |

|

|

Standard Configuration of X-6600 |

|||

|

Item |

QTY |

Unit |

Remark |

|

90KV-5um sealed X Tube |

1 |

pcs |

|

|

Object Table |

1 |

pcs |

size:520mm*450mm |

|

Flat Panel Detector |

1 |

pcs |

HD |

|

Image processor CPU |

1 |

pcs |

Complete function |

|

LCD |

1 |

pcs |

24’’ |

FAQ:

1. Is It safe to operate?

It is Safe!

We have CE,FDA certificate for X ray inspection machine.

Its X Ray leakage less than 0.3μSv/H when it isworking and the air radiation is 1μSv/H.It means our machine radiation less than air and the radiation amount within safety value

Our machines have been sold to Asia,Europe and North America already. Our machines comply with local regulations and requirements of radiography products.We can assist you to apply the license if it is needed!

2. Is it easy to operate ? I have no experience, can I also operate it well ?

Do not worry!It operated by mouse and keyboard, only take 1 hour to learn how to operate.

We also provide free training in our company.You are welcome to visit our company to be trained here. And we could arrange the engineer to go to your country/company to train your workers directly as your requested and the relative travel cost will be on your account.

3.What is the advantage of your product?

* Important material are imported. Xray Tube is from Japan, World TOP 3 x ray tube manufacturer.

Flat panel is from Korea which produce medical panels which make we could get high resolution image

* X ray machine are CE&FDA approved.

* We are original factory,the price is very competitive!

* Professional engineers and sales team provide the support for you

4. What is your package? Is it safe during the transport ?

X-6600 are packed in Solid wooden box with foam, sticks and band to fix inside. It is safe enough during the transport.

5.What is the warranty?

1 year warranty for spare parts, and Whole life technical support

Microfocus X-Ray inspect equipment X-6600 for PCBA solder inspection was added in Jun 2018

Microfocus X-Ray inspect equipment X-6600 for PCBA solder inspection has been viewed 657 times

20 More Products from Seamark Zhuomao Photoeletric technology(Shenzhen)CO., ltd :

.jpg)

1.png)