Small Pick and Place Machine

Company Information:

Name: |

Small Pick and Place Machine |

Category: |

|

Offered by: |

|

Small Pick and Place Machine Description:

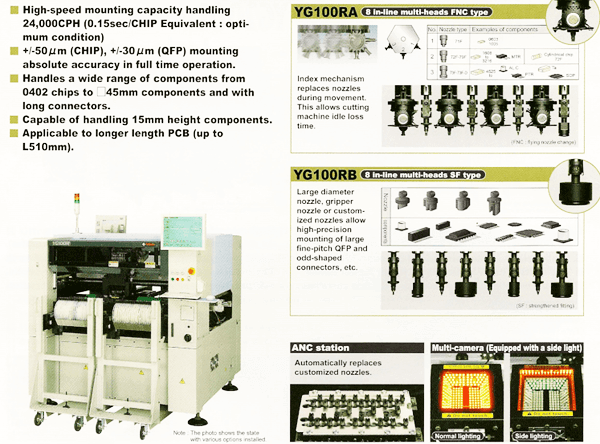

- Yamaha YG100 chip mounter

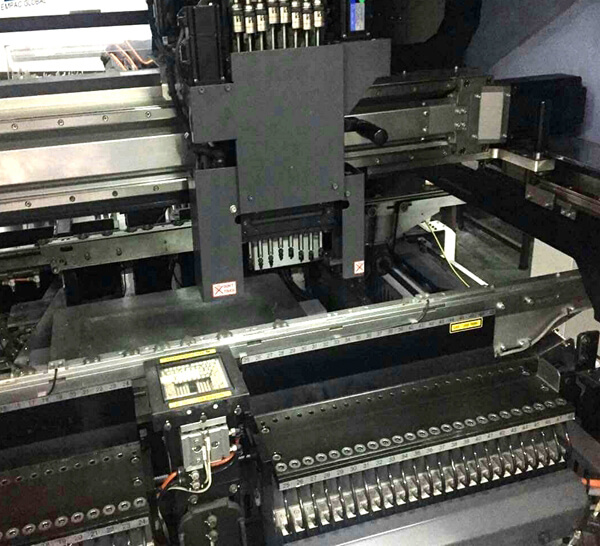

- 1,650(L)x1,562(W)x1,850(H)mm

- Patch speed: 24,000 CPH

- Weight: 1,630kg

- Product description: Small Pick and Place Machine, Patch speed: 24,000 CPH, Weight: 1,630kg, Dimension:1,650(L)x1,562(W)x1,850(H)mm

-

INQUIRY

Small Pick and Place Machine

Machine Details:

Yamaha YG100 chip mounter's vantage is from 2005 to 2010, mactching windows operating system.

Use single-arm) eight head mount patches, controlled by two motors, easy to maintain and installment,

The price range for used placement machine is about USD30000-USD50000(Only for reference).

YAMAHA YG100 chip mounter is a high-performance, high-precision placement machine produced by YAMAHA specifically

for high-speed general purpose machines,it can simultaneously mount different types of special-shaped

components.Using YAMAHA's newly designed head structure,all nozzles up and down control are controlled by

the electric motor, The machine mounting accuracy is greatly improved compared to the previous memory.

YAMAHA YG100 chip mounter high-speed placement chip, high-precision, high-speed modular placement machine,

high rigidity dual drive structure,High-performance servo system, high-resolution digital multi-vision camera,

multiple precision correction system.

Automatically adjust the transmission width, automatically adjust the height of the mounting surface,

belonging to the YG series classic models.The theory is 25,000 points per hour.

The actual production speed is about 15,000 points per hour.

1. YAMAHA YG100 chip mounter's advantages:

Mounting range from 01005 (Inch) micro-components to 45mm components.

Corresponding to the large substrate size L510xW440mm.

96 kinds of large component varieties.

Patch speed: 24,000 CPH (0.15 seconds/CHIP)

Mounting accuracy: (μ+3σ)±0.03mm/CHIP

Repeatability (3σ): ±0.03mm/CHIP

Mounting PCB Size: L50×W50mm~L510×W440mm

Component Types Belt Packaging: 120 types (converted to 8mm tape)

2. YAMAHA YG100 chip mounter's parameters:

SMD Components: 0402(MM)-45MMX45MM Components SOP SOJ PLCC QFP BGA

SMD components can be placed 100 kinds (8MM)

Mounter size: L1650XW1562X1470

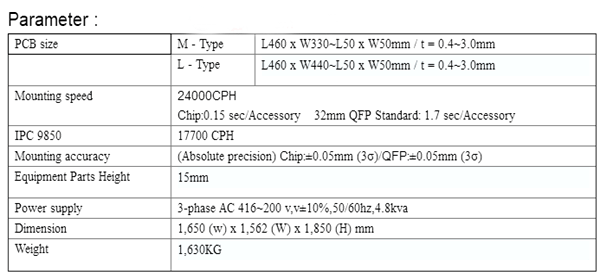

Yamaha YG100 chip mounter specification and details as following:

1) Board size: M-Type: L460xW330 ~ L50xW50mm/t = 0.4 ~ 3.0mmL-Type:

L460xW440 ~ L50xW50mm/t = 0.4 ~ 3.0mm * sATS use: L460xW440 ~ L50xW50mm

2) Mounting speed: Chip: 0.15 seconds / accessories / 32mm QFP standard: 1.70 seconds / accessories 3)

IPC9850 conditions: 17700CPH, Chip: 0.20 seconds / accessories

4) Mounting accuracy: Chip: ± 0.05mm (3σ) / QFP: ± 0.05mm (3σ)

5) Mounting angle: (0.01±180° units)

6) Supported components: 0402 to SOP, SOJ, 84-pin PLCC, 0.5mm pitch QFPBGA,

CSP□31mm, 100mm connector, IC socket.

7) Equipment Parts Height: 15mm

8) Part identification methods: multi-angle illumination digital multi-camera system (34 pixels),

multi-angle lighting good vision system (79 pixels).

9) Operation Software: YGOS (FullLine Mode, OnLineHelp, rich accessories and internal organs)

10) Optimization Software: Basic Services (Head and Feeder Numbers,

Automatically Specified by the Installer)

11) Remote Control Software: Select (OnLine and OffLine Functions Available

12) Communication port: (Ethernet has Lan&RS232C)

13) Safety device: Head collision protection device in two modes: SoftLimit and HardLimit.

The CoverInterlock switch is used for head and collision prevention.

14) Power supply: 3-phase AC 416~200V, V± 10%, 50/60Hz, 4.8kVA

15) Air supply: 5.5kg/ (DryAir)/140/min

16) Size and Weight: 1,650(L)x1,562(W)x1,850(H)mm

17) Weight: 1,630kg

3.YG100RA (FNC Model)/YG100RB (SF Model) Model: KHW-000 Serise Machine

Imagine substrate

L50×W50mm~L510×W460mm (Note 1) (Note 2)

Mounting efficiency

(optimal conditions)

24,000CPH/CHIP (equivalent to 0.15 seconds/CHIP)

Mounting accuracy

(Our standard components)

Absolute accuracy (μ+3σ): ±0.05mm/CHIP, ±0.05mm/QFP

Repeatability (3σ): ±0.03mm/CHIP, ±0.03mm/QFP

Object element

0402 (mm series name) - □ 55mm element) SOP/SOJ) QFP) connector) PLCC) CSP/BGA)

long connector (Note 3) (Note 4) (Note 5)

Target component height is 15mm or less (Note 6)

Component type

96 (maximum) conversion to 8mm reel) (Note 1)

Power Specifications

Three-phase AC 200/208/220/240/380/400/416 V ±10%50/60 Hz

Supply source

0.55MPa or more) clean and dry

Dimensions

L1,650×W1,562 (covered end)×H1,470 mm (above the cover)

L1,650×W1,615 (whole rail end of replacement trolley)×H1,470mm (above cover)

4.YG100RA(FNC type) / YG100RB(SF type)(Model : KHW-000)

Applicable PCB

L510xW440mm to L50xW50mm(Note 1)(Note 2)

Through-put (Optimum)

24,000CPH(0.15sec/CHIP Equivalent)

Mounting accuracy (Yamaha's standard components)

Absolute accuracy (μ+3σ):+/-0.05mm /CHIP, +/-0.05mm /QFP

Repeatability(3σ):+/-0.03mm /CHIP, +/-0.03mm /QFP

Applicable components

0402(Metric base) to □45mm components, SOP/SOJ, QFP,connector, PLCC, CSP/BGA,

Long connector (Note 3)(Note 4)(Note 5)

Height of components which can be mounted : 15mm or less(Note 6)

Number of component types

96types(Max,8mm tape reel conversion)(Note 1)

Power supply

3-Phase AC 200/208/220/240/380/400/416V +/-10% 50/60Hz

Air supply source

0.55MPa or more, in clean, dry states

External dimension(Note 7)

L1,650xW1,562(End of cover)xH1,470mm(cover top)L1,650xW1,

615(End of guide for feeder carriage)xH1,470mm(cover top)

Weight Approx. 1,630kg(Main unit only)

Keywords:

JUKI RS-1R pick and place machine, JUKI RX-7R pick and place machine, Hanwha SM481 Plus Pick and Place Machine, Hanwha SM482 Plus Pick and Place Machine, SMT pick and place machine, JUKI Pick and place Machine, Samsung Pick and Place Machine, Hanwha Pick and place machine, Yamaha Pick and Place Machine, Panasonic Pick and Place Machine, FUJI Pick and Place Machine, Siemens Pick and Place Machine.

QISMT Co.,ltd provide a full SMT assembly line solutions, including SMT Reflow Oven, Wave Soldering Machine, Pick and Place Machine, SMT Stencil Printer, SMT AOI SPI Machine, SMT Peripheral Equipment, SMT Production line, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: wechat whatsapp:+8617748683433, Skype: qismteric, Email: sales@qismt.com

FAQ

1) This is the first time I use this kind of machine, is it easy to operate?

There is English manual or guide video that show you how to use machine.

If you still have any question, please contact us by e-mail / skype/ phone /trademanager online service.

2) If machine have any problem after I receive it, how can I do ?

Free parts send to you in machine warranty period.

If the part is less than 0.5KG, we pay the postage.

If it exceeds 0.5KG, you need to pay the postage.

3) MOQ ?

1 set machine, mixed order is also welcomed.

4) How can I buy this machine from you? ( Very easy and flexible !)

A. Consult us about this product on line or by e-mail.

B. Negotiate and confirm the final price , shipping , payment methods and other terms.

C. Send you the proforma invoice and confirm your order.

D. Make the payment according to the method put on proforma invoice.

E. We prepare for your order in terms of the proforma invoice after confirming your full payment.

And 100% quality check before shipping.

F.Send your order by air or by sea.

5)Why choose us ?

A. Gold supplier on Alibaba !

B. Trade assurance to US$54,000 !

C. Best price & Best shipping & Best service !

CATEGORIES

CONTACT US

Contact: Eric

Phone: +86 17748683433

Tel: 0755-85225569

Add: No.94, Guangtian Road, Songgang Street, Bao`an District Shenzhen

When SMT matters to your business, partner with QISMT. Where innovation takes form. Mr Eric. sales@qismt.com Wechat whatsapp:+86177 48683433 skype:qismteric

Small Pick and Place Machine was added in Oct 2021

Small Pick and Place Machine has been viewed 19 times

20 More Products from qismt electronic co.,ltd :